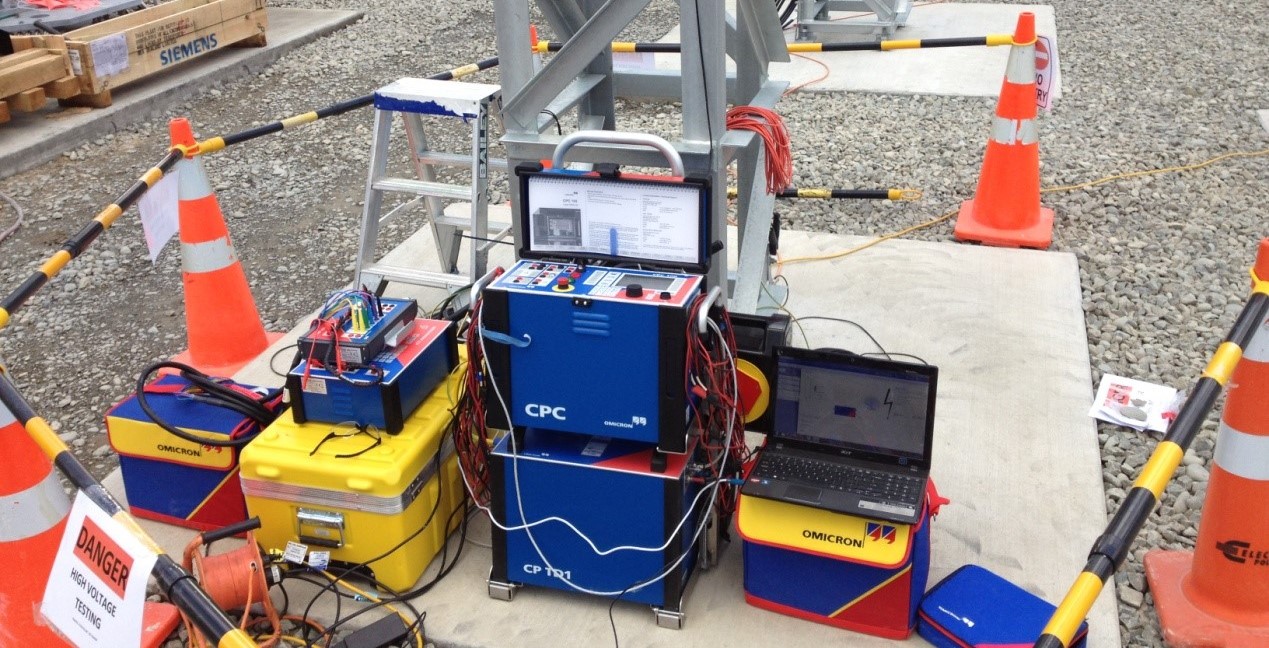

New or Altered Installations

In Australia, HV auditing is mandated in the Electricity Act. According to the legislation, all new and altered HV installations must undergo an audit before they can be energized. The responsibility for ensuring compliance resets with the high voltage asset owners. While the regulations may vary from state to state, specifics slightly vary.

The HV audit for new or altered installations ensures that the design and construction meet the safety and compliance standards set forth in the relevant legislation. The audit process involves a detailed investigation of the installation’s design, equipment compliance, and operational procedures, ensuring that the system can be safely connected to the power grid.